Anodizing

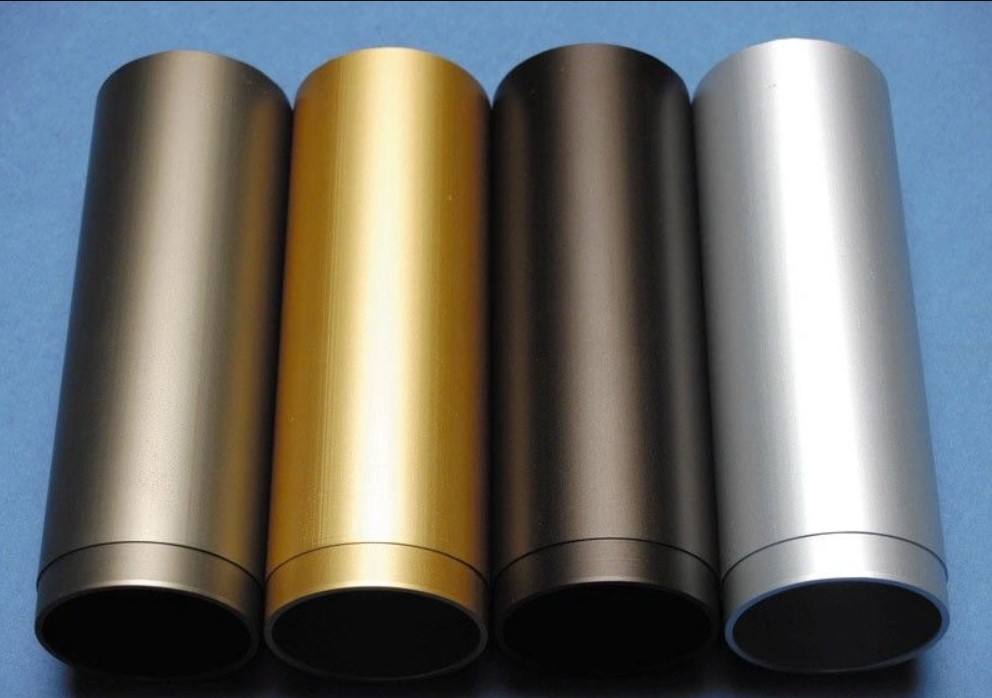

Metal Anodizing: Enhancing Durability and Performance

A primary factor leading to the deterioration of original metal product properties is the chemical interaction of their composition with oxygen, resulting in the formation of corrosive layers that compromise their strength. To proactively address this issue and prevent its occurrence, additional treatments are undertaken. This process, known as chemical oxidation or anodizing in technical terminology, is a specialized service offered by our company. The total cost of the service is influenced by factors such as the quantity of items submitted for processing and the specific technique employed.

Methods of Treatment

The application of an oxide layer onto metal surfaces is accomplished through various methods, including:

-

Thermal Technology: This approach is suitable for steel anodizing, while materials like aluminum may not withstand the associated conditions. Temperature ranges, typically between 300-1200 degrees Celsius, are chosen based on the alloy composition. The process is conducted within an acidic environment or using water vapor.

-

Electrochemical Method: Electrochemical metal anodizing entails the application of a positive potential across the oxidized surface, creating a wear-resistant dielectric layer with enhanced durability.

-

Chemical Technology: The quality of the chemical oxidation procedure hinges upon the appropriate selection of reagents. This process occurs in dedicated equipment with controlled temperature settings, varying between 100 to 180 degrees Celsius depending on the chosen medium – alkaline or acidic. Once the process is complete, the oxidized alloy is washed and dried.

-

Microarc Machining: Frequently combined with electrochemical processing, this method differs in potential distribution across the treated surface. Microarc technology results in a dielectric outer layer constituting about one-third of the entire surface.

Key Aspects of Pricing

Contrary to common assumptions, achieving reliability, practicality, and quality does not necessarily entail overbearing costs. Pricing varies among companies in the local market, shaped by general parameters:

-

Part Geometry: The complexity of the part's shape directly influences the level of difficulty in processing, thereby impacting the overall cost.

-

Type of Material: Different types of metals – steel, aluminum, or titanium – necessitate specific technologies and materials, influencing the pricing accordingly.

-

Order Volume: Sizeable customers, such as manufacturers, decorators, and designers with recurring orders, are often eligible for discounts.

-

Processing Timeline: While all orders follow a queue, expedited processing options are available for an additional fee, accommodating urgent requirements.

By utilizing advanced anodizing techniques, we empower metal products with heightened resistance to corrosion and wear, ensuring their longevity and performance across diverse applications.

+39 035 236452

sale@triestepg.com

Trieste Procurement Group SRL

Via Sant'Alessandro, 24122 Bergamo (BG)